Production & Quality Management

When you put on a set of GT Radial tires on your vehicle, you can be confident that your tires have been put through one of the most rigorous and comprehensive quality control systems in the industry.

QUality Control system

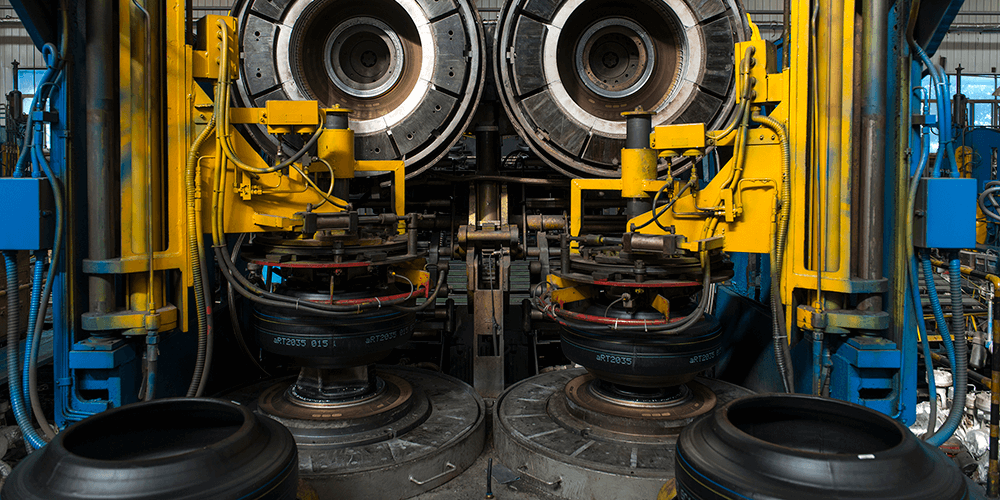

GT Radial has implemented a comprehensive quality control system at all seven of its tire plants. Strict quality control measures ensure that the quality of raw materials meet required specifications. GT Radial also conducts inspections at each stage of the production process to ensure that each component meets relevant specifications and standards.

GT Radial subjects tires to a final inspection before packaging them for delivery. With the use of an internal numbering system, the factories and distribution centers are able to monitor the employee group responsible for a particular production process, for each tire that is produced.

Part of the efforts to keep improving quality and safety standards include a single barcode located on the tire’s sidewall for backward tracing from the raw materials used all the way to the final product.

Operational Excellence and EHS (Environmental, Health and Safety)

Giti Tire is fully committed to maintaining the highest standard of quality control procedures. All plants have obtained ISO/TS16949:2002 accreditation (a highest standard of quality control) and ISO14001 Environmental Management System Accreditation.

Giti Excellent System governs not only operational excellence and efficiency but also employee health and safety in the work place and environmental sustainability by reducing natural resources and increasing reuse/recycling.

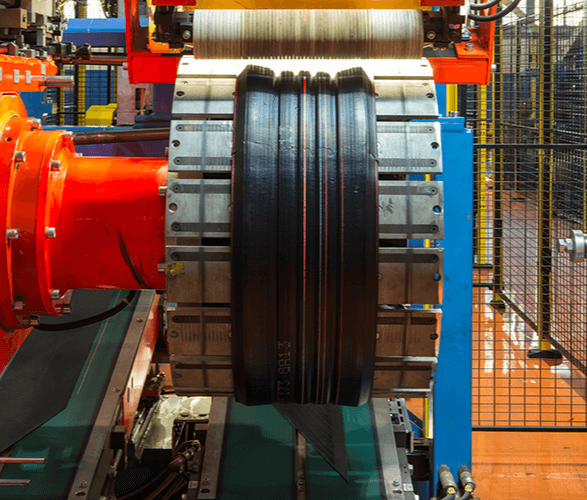

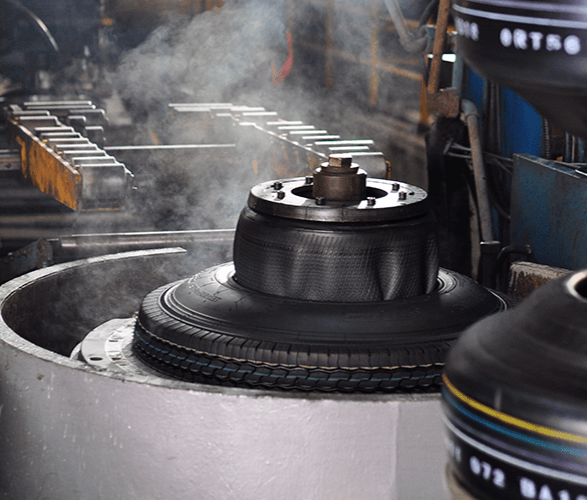

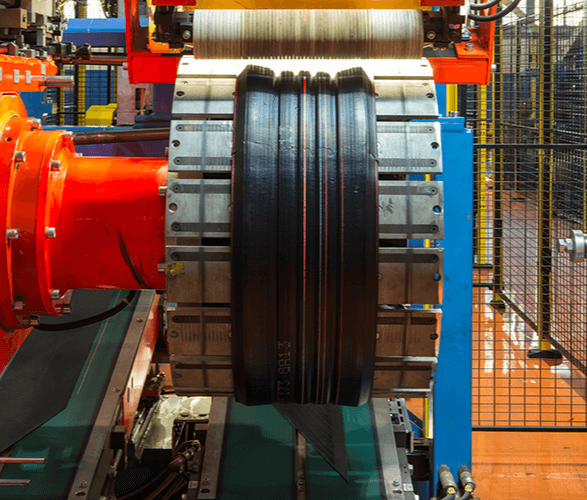

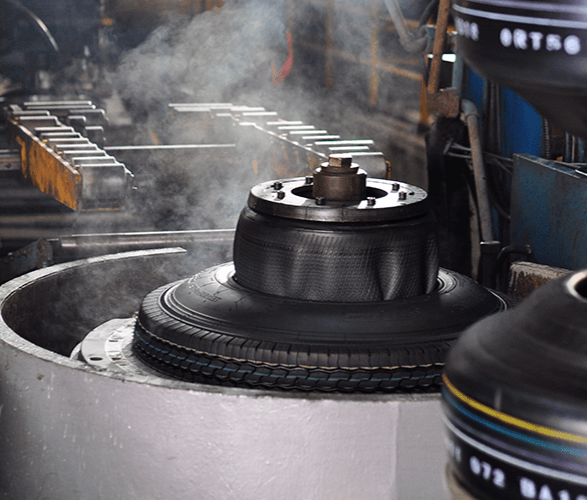

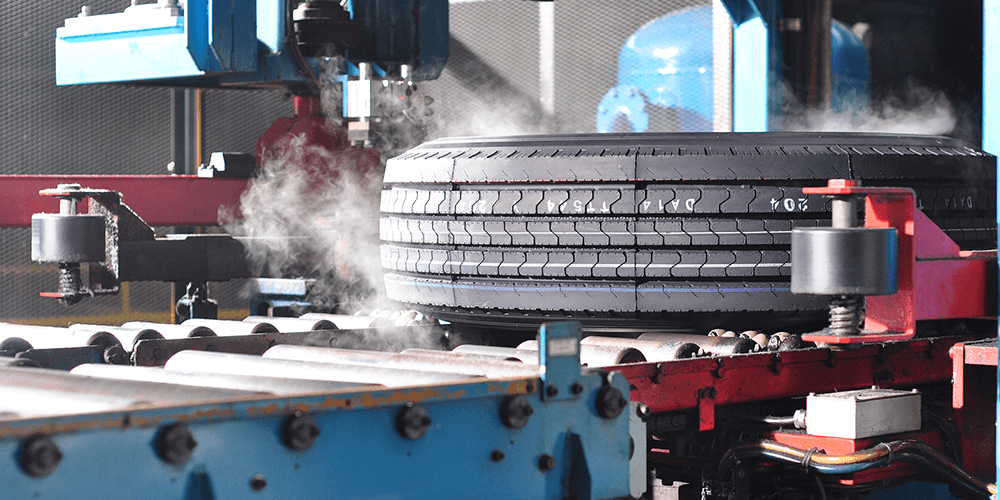

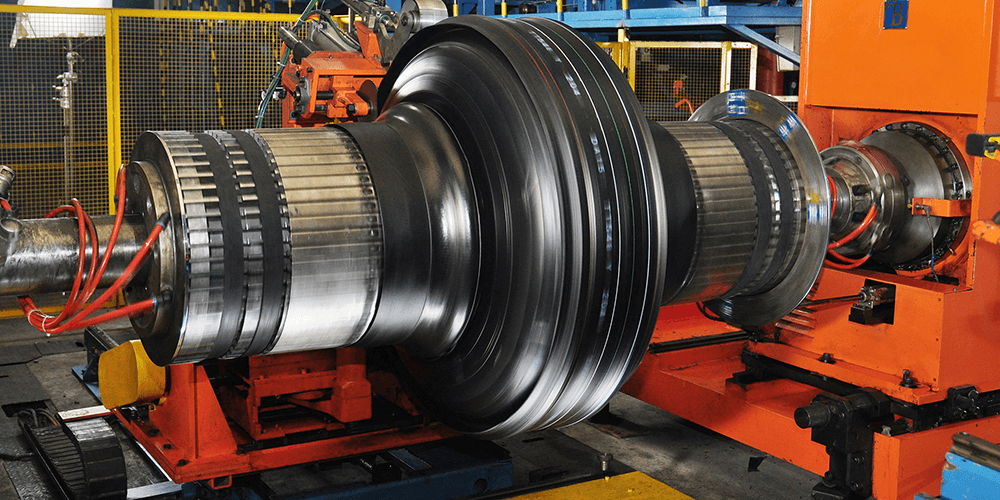

Tire Production Process - Meticulous and Complex

Tire production requires the best men, materials, machines, and processes. Giti Tire employees are passionate about building a better and safer tire. Below is an illustration on how tire is produced from raw materials, mixing, building, curing to the final products and Giti Tire’s relentless desire for improvement to ensure consistent quality

GT Radial has attained key international certifications for products in terms of quality and safety.

Top Class Research & Development

GT Radial has a team of over 600 experienced R&D engineers in five cutting-edge facilities around the world, ensuring the highest quality of tire production. We invest heavily in top-quality equipment and technology, and use the latest and most advanced tools and equipment to ensure that every tire we produce meets our exacting standards.

Making World-Class Tires

In 2013, GT Radial added two new R&D centers in the Unites States and Germany to the existing three centers in China, Indonesia, and the United Kingdom to further improve R&D capabilities around the world. With a team of over 600 experienced R&D engineers working closely throughout the five centers, GT Radial continues to enhance brand competitiveness and brand position to become a market leader.

Giti Excellent System governs not only operational excellence and efficiency but also employee health and safety in the work place and environmental sustainability by reducing natural resources and increasing reuse/recycling.

International Experience with a Multinational Background

GT Radial’s R&D personnel are made up of 20 different nationalities, creating a diverse atmosphere with cumulative knowledge and expertise. When combined with state-of-the-art tools and methods, GT Radial is enabled to produce technology driven products for improved and sustainable profitability while driving new market opportunities.

GT Radial ETC (European Technical Center)

GT Radial has made a significant investment in a European tire testing facility, hosted at the internationally acclaimed MIRA Ltd Proving Ground (previously called Motor Industry Research Association) at Warwickshire, just outside of Birmingham, UK. ETC consists of highly experienced tire testing and development staffs to provide development and evaluation capacity to GT Radial's R&D Center in China.

Proving Grounds

If indoor testing is successful, tires will be incorporated in one or more of the four GT Radial Proving Grounds located in: China (Anhui and Taiwan), the United Kingdom, and Finland (for winter tires).

On the test tracks, skilled drivers put tires through the paces to measure:

Handling and Stability at High Speeds

Riding Comfort

Wet Handling

Braking and Cornering

Noise Levels (both inside the vehicle and outside)

Then, and only then, is the tire ready for the market. When you purchase a brand produced by GT Radial, you can do so with confidence in the fact that it was born from one of the most strenuous R&D programs in the tire industry.

Preservation & Protection of Environment

In each of GT Radial's seven plants, the company sets the highest standard of quality control procedures. A highly strigent quality control system and concern for exceeding the safety and quality demands in regions across the globe separates the brand from the competition.

Tire Usage Perspective

More than 60% of the world’s oil output is used in transportation. In Trucks / Buses, tires contribute to approximately 30% of fuel consumption, or one full tank on every 3 Trucks / Buses, that can be saved by using the right tires with correct maintenance.

After years of research, GT Radial successfully developed tire production that consumes less fuel without sacrificing performance, and is verified by the US Environmental Protection agency, SmartWay.

In addition, GT Radial continually attempts to educate the public about the most fuel efficient ways to make use of a tire, how to select and maintain energy saving tires while providing the most professional solutions, and giving advice to fleets and users on how to reduce fuel consumption and cost. By providing the right tires and relevant technical support, GT Radial will help promote sustainable development of the industry while creating environmental benefits to the society.

Tire Manufacturing Perspective

Energy and non-renewable raw materials are becoming scarcer and more expensive. Optimizing their use and conserving them over the long term is essential. The challenge is to meet all of these goals without sacrificing tire performance, while being mindful of our responsibility to the environment and the people who live in it.

In this way, GT Radial is committed to reducing air emissions, water emissions, scrap and indirect materials, while increasing reuse/recycling.

Environmental Conservation Perspective

GT Radial’s parent company has donated USD $1 million for 260,000 hectares of conservation projects in various areas, through a partnership agreement with Conservation International (CI).

Protecting these forest areas from conversion into vegetation with lower biomass (tree plantations or agriculture) conserves about 100 tons of carbon per hectare, or 26 million tons of carbon in total. This is equivalent to about 100 years of carbon emissions resulting from coal burning at GT Radial plants.

News & Events

GT Radial To Burn Up the Track at the 2025 Formula Drift Championship

GT Radial returns to leave competition in the dust at the 2025 Formula Drift

GT Radial Wins First Formula DRIFT USA Event

GT Radial earned its first Formula DRIFT win this weekend when Chelsea Denofa captured his first Formula DRIFT victory in the season opener at the Streets of Long Beach.

Walmart USA Awards Giti Tire Automotive Supplier of the Year and Hardline Supplier of the Year Honors

Giti Tire has been named Automotive Supplier of the Year and Hardlines Supplier of the Year by Walmart USA. Giti took home the prestigious awards at the Walmart USA 2016 kickoff meeting in Indianapolis, Ind., on February 11-12.

Success Story

Giti Tire’s high levels of production efficiency, quality control, and driving experience have won the accolades of automotive companies and drivers from around the world.

- Outstanding Supplier Award

- 2008 and 2009

- Outstanding Supplier Award for 4 consecutive years,

- Cooperation Contribution Award 2010 and 2012, 2012

- Quality Contribution Award

- Most Outstanding Supplier Award

- for 8 consecutive years

- Most Outstanding Supplier Award

- for 5 consecutive years

News & Events

GT Radial To Burn Up the Track at the 2025 Formula Drift Championship

GT Radial returns to leave competition in the dust at the 2025 Formula Drift

GT Radial Wins First Formula DRIFT USA Event

GT Radial earned its first Formula DRIFT win this weekend when Chelsea Denofa captured his first Formula DRIFT victory in the season opener at the Streets of Long Beach.

Walmart USA Awards Giti Tire Automotive Supplier of the Year and Hardline Supplier of the Year Honors

Giti Tire has been named Automotive Supplier of the Year and Hardlines Supplier of the Year by Walmart USA. Giti took home the prestigious awards at the Walmart USA 2016 kickoff meeting in Indianapolis, Ind., on February 11-12.